SMD B120.V2 WOOD TRAY PACKER

SMD's B120v2 wood tray packer gives you productivity gains

SMD, Stitching Machine Development, designs, manufactures, installs, and monitors its machines to optimise your production line and control your costs.

To make packaging more environmentally friendly, SMD has designed machines using a natural material – wood – and more intelligent and efficient production lines.

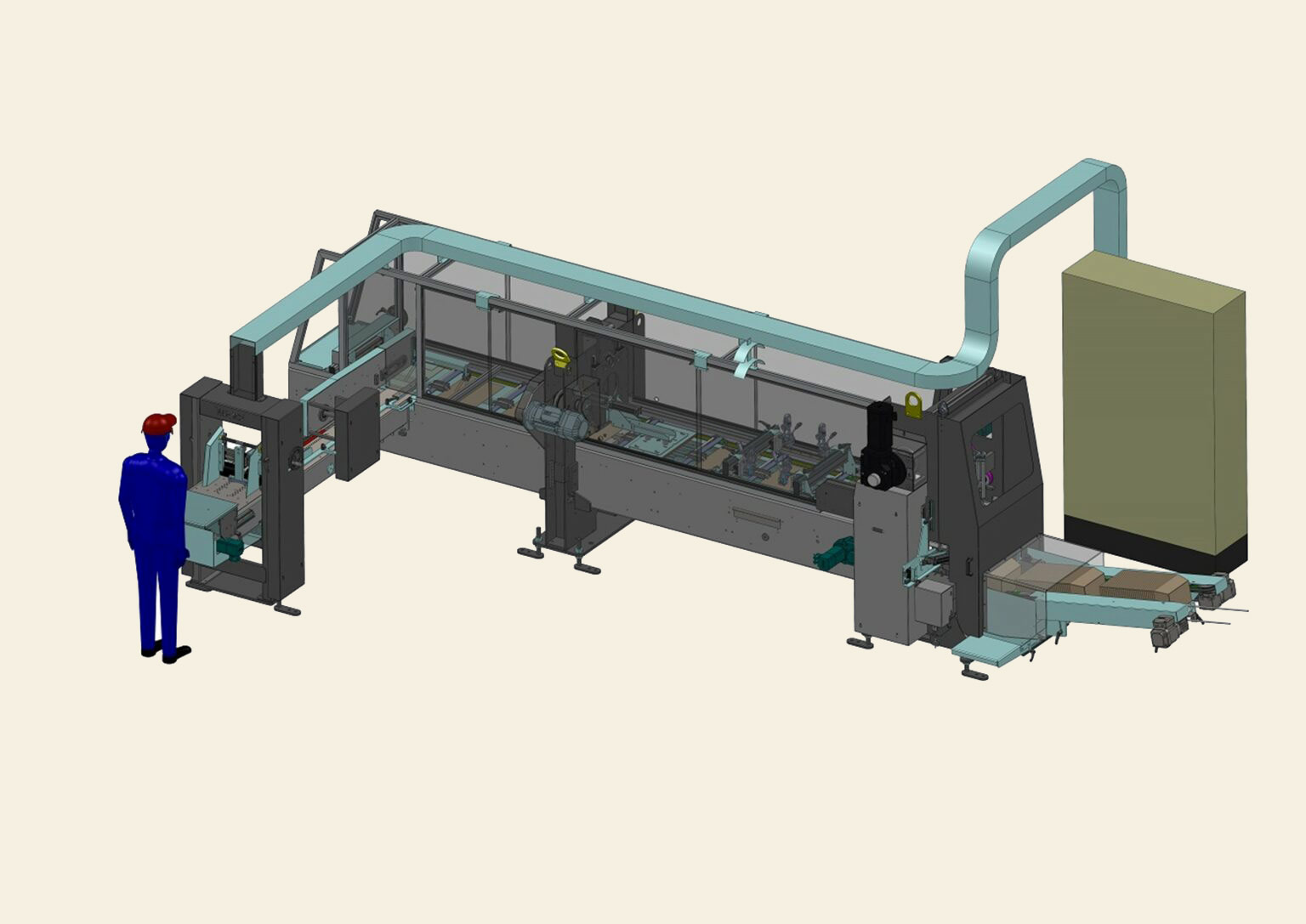

With this machine, SMD is extending its capabilities by thermoforming sheets of wood up to 3 millimetres thick.

The wooden tray in video...

HIGHLIGHTS

- Innovation: thermoforming of thick sheets of wood (patented system)

- Productivity: 3,600 wooden trays/hour

- Sheets: from 120x140mm to 310x580mm / Thickness from 1 to 3 mm

- Trays: width 55 to 200 mm x length 70 to 300 mm x height 25 to 110 mm / taper 10° to 30°

- Possible options: closing by stitching, gluing or locktab (without stitches or glue), inkjet printing

A more ecological tray packer

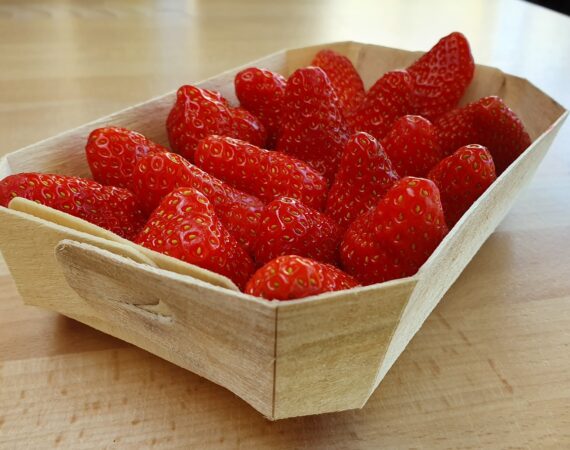

With the B120.v2 wooden tray packer, you can offer your customers trays made from a noble, high-quality material that showcases your expertise and food products – fruit and vegetables.

Wooden trays, specially designed for cooking or reheating in traditional or microwave ovens, preserve flavours and ensure better preservation thanks to the transfer of moisture between the wood and the food.

Thanks to wood, which is biodegradable, reusable and healthy for your customers and the planet, you can offer an alternative solution to plastic trays, minimising the ecological impact.

Constantly innovating

The B120.v2 wood packaging machine is constantly being improved to offer you ever-thicker wood trays, in a range of standard and non-standard formats (see models below), to optimise your production and transport costs.

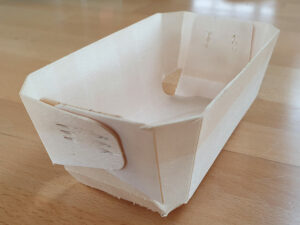

From a sheet of peeled poplar wood, you can produce a tray that can be filled and then assembled, with several closing options (stitching, gluing, locktab (without stitches or glue)).

Depending on your needs, we can design different tray formats to showcase your product and meet the demanding and fluctuating demands of the market.

With a throughput capacity of 3,600 trays/hour, you can produce up to 25,000 trays/day on average with 2 operators.

The stages involved in designing your wood tray packer with SMD.

By entrusting your project to the SMD teams, you can be sure of getting a solution adapted to your production needs.

First, we take the time to talk to you and visit your premises to fully understand your needs. It’s essential for us to be in line with your expectations. We want to understand your need to improve productivity, your resource constraints, so that we can offer you the right solution from our range of machines…

We then go on to study the feasibility of your project and prepare a proposal based on our discussions. Once this proposal has been accepted, we launch production of your machine.

Each module is tested on our premises to guarantee the highest level of reliability. We carry out both mechanical and automation tests. We then assemble all the modules on site, followed by final tests.

When the final tests are conclusive, we organise transport of the machine to your workshops.

Our support doesn’t stop there: we then install the machine on your premises and carry out further tests. And to make sure your teams get the hang of it; we take the time to train them in its use.

Finally, we remain available after installation if you need us: we can carry out remote troubleshooting. And if that’s not enough, we’ll come to your premises to provide after-sales service for your machine, to make sure your complete satisfaction.